There are some artefacts of industrial history that are more important than others, and therefore more deserving of preservation and acknowledgment. Amongst these has to be the 'Griffiths' windmill.

This is the first commercial windmill design produced by the partnership that became 'Southern Cross'. Southern Cross are probably the best known Australian windmill manufacturer world wide and one of the major windmill manufacturers in the history of the windmill in Australia.

There are a number of considerations that can be thought of as prerequisites for the manufacture of the Griffiths windmill in 1876.

One requirement was the ability to fabricate the mill itself. Although Griffiths Brothers while operating as blacksmiths had two small forges and other limited engineering equipment such as a lathe and drill, it was not until the beginning of 1876 that foundry facilities were available to them for casting larger parts such as a hub.

There would also have needed to be a basis of design expertise preceding the construction of the first windmill. The foundry's history grants that the design was taken from a pre-existing American manufactured machine owned by Sir Joshua BELL, part owner of 'Jimbour' station. Even at this date the particular design chosen was fairly unconventional, and its choice and continued use in various models until 1893 probably restricted the company's competitiveness in the windmill market.

Lastly the commission from BELL, for the four windmills, created a market.

Information concerning the construction of the 'Jimbour' station mansion, which commenced in 1874, states that the windmill erected at that location for domestic supply was the first windmill in Queensland, and came from California. The first point is perhaps open to dispute on a state-wide basis, but is at least relevant to the local history. The small settlement of Jimbour is about 25 kilometres from Dalby, which itself is 85 kilometres from Toowoomba. This would make it fairly convenient for the Griffith's brothers to measure and copy the American mill.

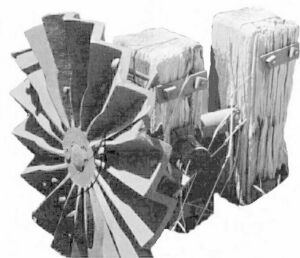

Company history lists the windmills as being direct acting with wind wheels and towers constructed of wood. A further significant notation is a comment that, later on, the company produced a lighter windmill, with the turntable located on top of the tower, which the illustrated machine certainly isn't, having its turntable on the cross beam supports, well down the tower.

The following description of one of these windmills by Mr C.J. WATERS was written in 1992. His property where the windmill stood is thought to be part of the old Jimbour Station.

"The four [wooden] legs were sunk into the ground for 5 or 6 feet, but from ground level to turntable, about 25 feet was broad axed to perhaps 10 inches by 6. The wooden turntable was round and bound with an iron ring - just like the tyre of a dray or wagon. Legs were secured to this by huge, 1 inch bolts. The arms to hold the fans were originally of cedar, but replaced later by hardwood [Spotted Gum]. The crown wheel [hub] to which the arms were fitted was a magnificent piece of moulded cast iron, with a 3 inch shaft running across on wooden bearings.

Even after 50 to 100 years, the wear was hardly noticeable and smooth as silk. Unfortunately this mill [although in good order] was in the path of a violent wind storm and being slow to turn out of the wind, was twisted out of repair."

He further stated that there were two such windmills on his station. This windmill was apparently erected by local tradesmen and was eventually pulled down about 1950. The tower could be of local construction.

Another similar windmill appears to have been erected on the Myall Creek, nearby.

Along with that additional information, we have also become aware that there is enough of one of these mills to base a reconstruction on. Along with photographic detail and a fine scale model, which could be used as reconstruction guides, there exists at least one set of the metal work for the mill, and parts of the woodwork from which to obtain original measurements.

It appears that Jimbour Station purchased more than the original four windmills. John FERGUSON, since deceased, one of the workers on Jimbour early in the twentieth century, is reported to have said that there were eleven of these windmills that he had worked on. Whatever the number, it seems that we are not in a position to say with any certainty that the particular windmill we know of is one of the original four. It does however, appear almost certainly to have been of that design, and built in that short period. In later years the original station has been broken up and several properties formed from it.

As at least one hub, similar in design but smaller in size, has been found in the area, it is possible to conclude that not all of these windmills were the same size, and there may also have been other slight variations in the design between individual units. The windmill portrayed in Fig.1 may be the largest size of the model produced.

Additional detail about the windmill includes the description of the head, stating it to have a hub shaft about 4cm to 7.5cm in diameter, and about a metre long. The wooden shaft bearings' lubrication was by oil reservoirs and wicks. The pump stroke was obtained from a wrist pin in a cast disc of about 25cm diameter, fitted at the front of the shaft, and the wooden pump rod attached directly to the wrist pin.

To furl the windmill, a long lever hinging on the turntable support beams was used to pull the large tail vane sheet into an upright position to face the wind. The wooden vane shaft turned in two iron rings. As the large vane caught the wind, it turned the whole windmill out of the wind. A counterweight on the axis of the large vane shaft was used to set the regulating speed. The tower cross pieces that held the turntable were about 30cm square and were morticed and tenoned.

The wind wheel was composed of paddle type blades and formed into a shallow cone shape with the tip of the cone pointing into the wind. To hold this shape a light metal band was fitted near the outside edge of the wheel.

At the top of the windmill legs, a guide ring for the windmills mast was fitted. The guide ring had metal cylindrical rollers in half moon metal housings, to allow the windmill to turn easier.

N.B As the Griffiths windmill was produced by a Queensland firm and sold to a significant Queensland property, the owner of the parts and pattern has expressed the desire for the windmill, if restored, to remain local to the state.

This article is reprinted from Vol.2 No.1 pages 5-6 of The Windmill Journal of Australia and New Zealand. Web page layout differs from printed page.